PX-DIR103 large-area infrared inspection, fast and efficient, detection not limited to the ground

The PX-DIR103 photovoltaic unmanned aerial vehicle thermal imaging inspection and testing equipment is applied to the thermal imaging inspection of photovoltaic power stations. It is efficient and portable, and the high-precision detection module can perform fixed-point or large-area inspections. The independently developed Al recognition software system automatically generates diagnostic reports. The PX-DIR103 adopts a high-frequency infrared camera imported from Germany for unmanned aerial vehicle flight detection, with an imaging quality of up to 125Hz, which can present more detailed hotspots and has real-time temperature recording function, presenting users with the most authentic temperature data.

Performance characteristics:

1. GPS trajectory inspection

2. 125Hz high-frequency analysis

3. Automatic photo taking for thermal glass monitoring

4. GPS positioning analysis

5. Automatic recognition of software hot spots

6. Picture in Picture Positioning Query

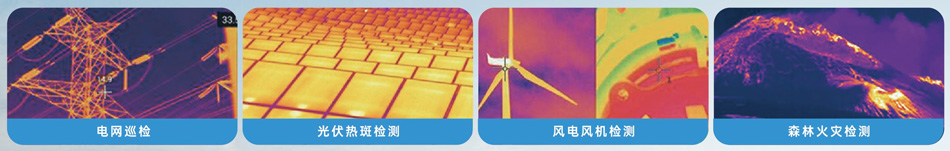

Application area:

Technical parameter:

| Specification and model | PX-DIR103 |

| Performance index | |

| UAV | DJI M300 RTK |

| Gimbal | Mobile visible light camera and infrared camera share gimbal |

| GPS | DJI GPS module |

| Visible light camera | 20 million pixel zoom camera; 12 million pixel wide-angle camera; |

| Battery | TB60 |

| Battery life | No load: 55min load 2kg: 30min |

| Remote control distance | 5 KM |

| Tablet PC | ipad(apple) |

| Thermal imaging resolution | 640x512 |

| Detectable defect types | Heat spot attenuation, power system, temperature difference, temperature display |

| Detection efficiency | 1MW/15min |

| Infrared detector | Focal plane array (12umX12um) |

| Test temperature range | -40--150℃,-40--550℃ |

| Working temperature | -20℃~50℃ |

| Frame rate | 30HZ |

| Field of view angle | 45x45 |

| Thermal sensitivity | <50mK@f/1.0 |

| Accuracy | +2℃ or 土2% |

| Power Supply | |

| Software metrics | |

| Real time temperature | Real time display of aircraft process hot spot temperature |

| Patrol hovering | Cruise detection detects temperature points such as hot spots and automatically hovers, and dual light images are taken |

| GPS trajectory inspection | Automatic trajectory inspection, fixed-point photography or video recording, and automatic return after inspection is completed |

| Thermal image analysis | The software displays real temperature data by clicking on different temperature points based on infrared image data |

| Hot spot recognition | Can directly perform automatic anomaly detection and detection from images without manual intervention, automatically mark and record location information; Automatic recognition of hot spots with an accuracy rate of 80% |

| Manual marking | By browsing thermal infrared photos, the location and type of the fault point in the photo can be manually marked. |

| Fault diagnosis | Can automatically diagnose the causes (faults) of hot spots without manual intervention, and can automatically identify the types of faults |

| Picture in Picture Settings | Can combine visible light images with thermal imaging images to present picture in picture, facilitating fault localization |

| Image localization | Ability to add information on marked fault points, calculate the actual geographic location of each fault point based on GIS map, and display it on GIS map. The identification can be accurate to component blocks (within 1 meter) |

| Report generation | Fast and simple analysis of flight data collection, effectively associating all aerial and thermal imaging photos with fault location points, and quickly generating editable accident reports on site |

Previous:Drone EL inspection equipment

Next:No